Related projects

About the Rheology Lab

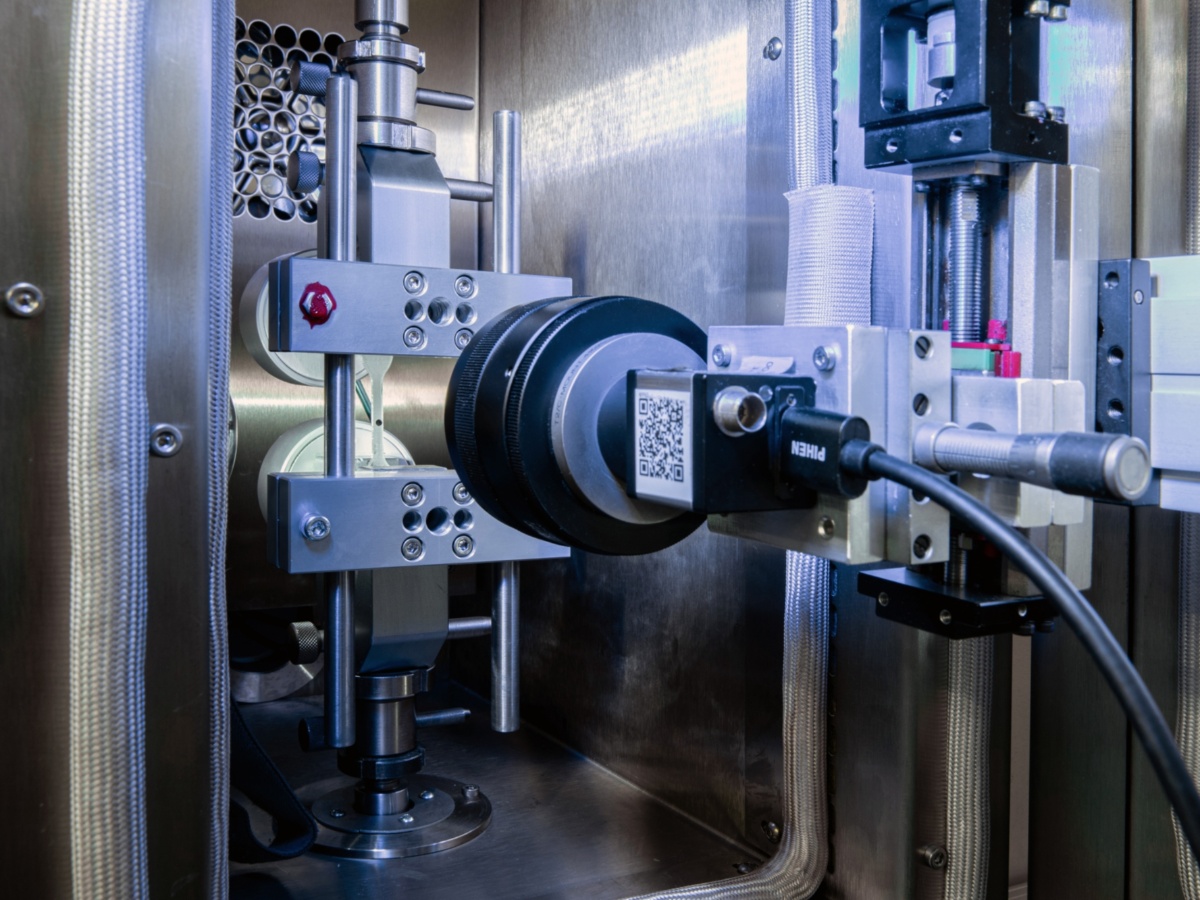

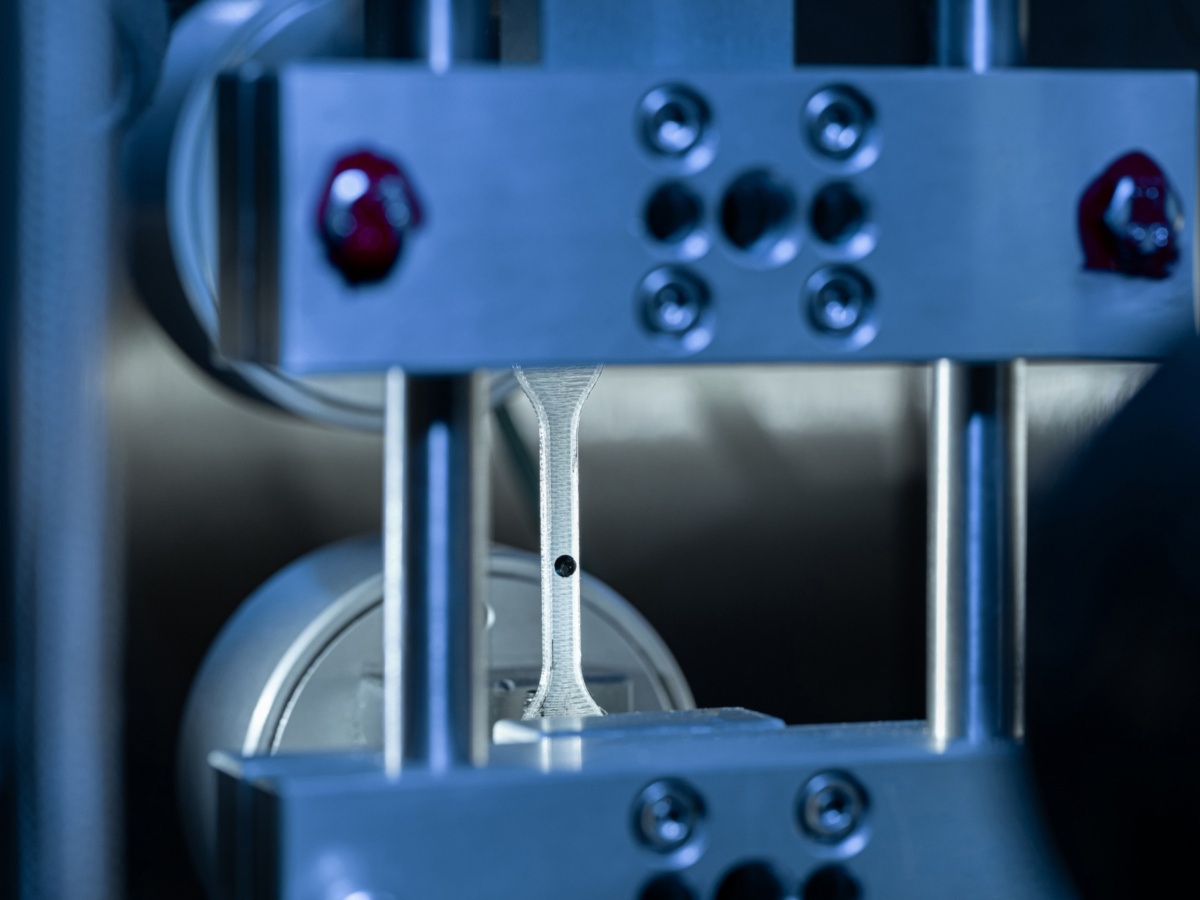

The Rheology Lab creates a framework in which DMA (Dynamic Mechanical Analysis) respectively DMTA (Dynamic Mechanical Thermal Analysis) for soft materials can be carried out. The main component in the Rheology Lab is the Anton Paar MCR 502 WESP TwinDrive rheometer, which can be equipped with an additional second motor. On the one hand, a rotational motor allows for torsional or shear experiments with increased torque and frequencies, while on the other hand a longitudinal motor enables harmonic excitations in axial direction. Thus, within one setup and using only one sample, two different loading scenarios can be investigated in order to determine the small-strain Young's modulus and shear modulus. Moreover, there are different temperature chambers available in the PML to be added to the rheometer, making it possible to control the temperature (and humidity) inside each chamber.

- The Peltier element heated/cooled chamber Anton Paar CTD 180 has a temperature range from -20°C to 180°C.

- Using ProUmid's MHG100 humidity generator, the CTD 180 temperature chamber can be extended to control humidity in the range of 5 to 95%rH (while keeping the temperature inside the range of 5 to 100°C).

- Another possibility is to equip the rheometer with the Anton Paar CTD 450 convection heated temperature chamber. By this, applying temperatures from -150°C to 450°C (employing liquid nitrogen for cooling) is feasible.

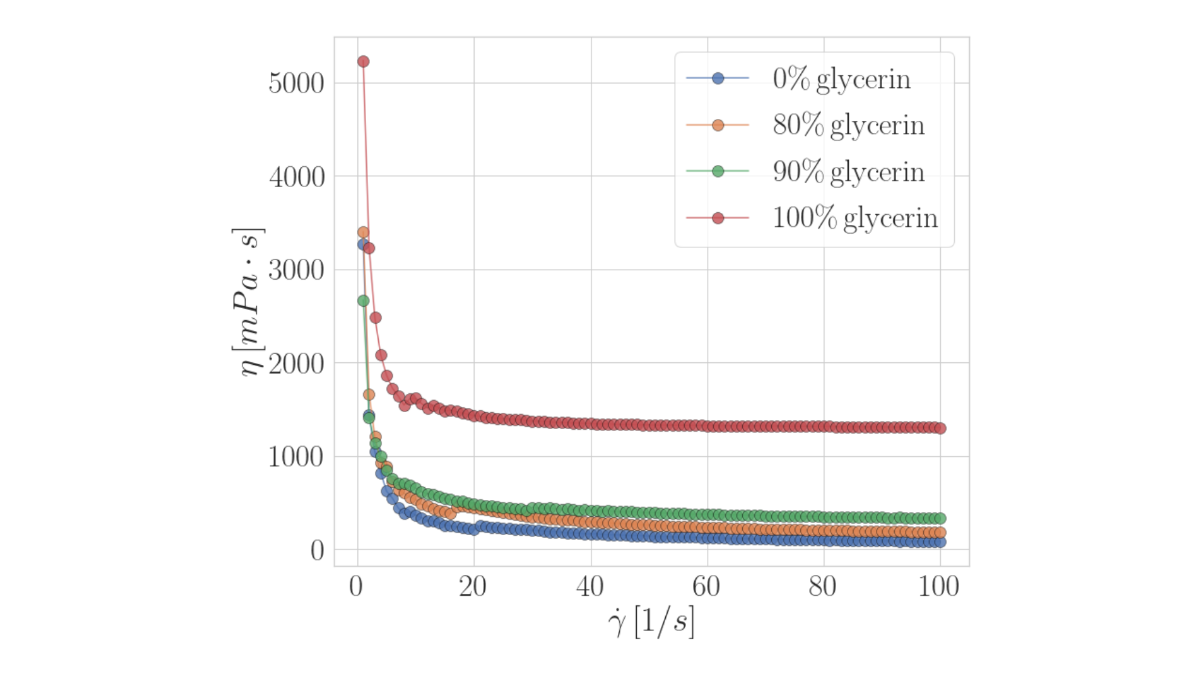

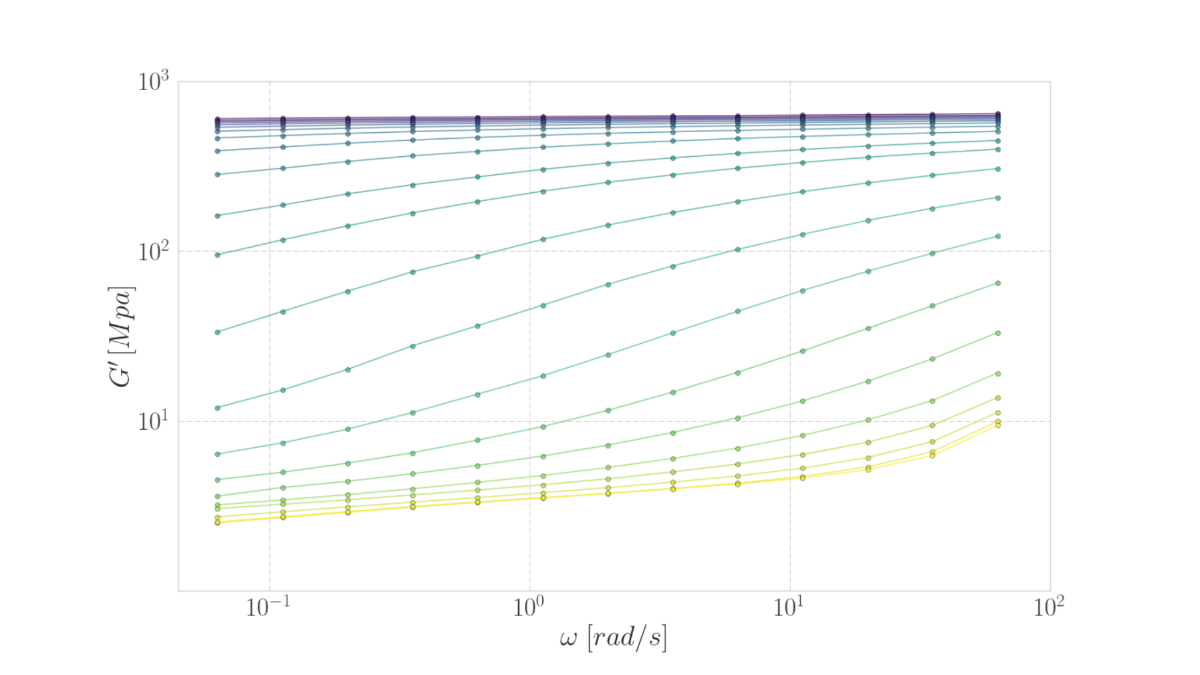

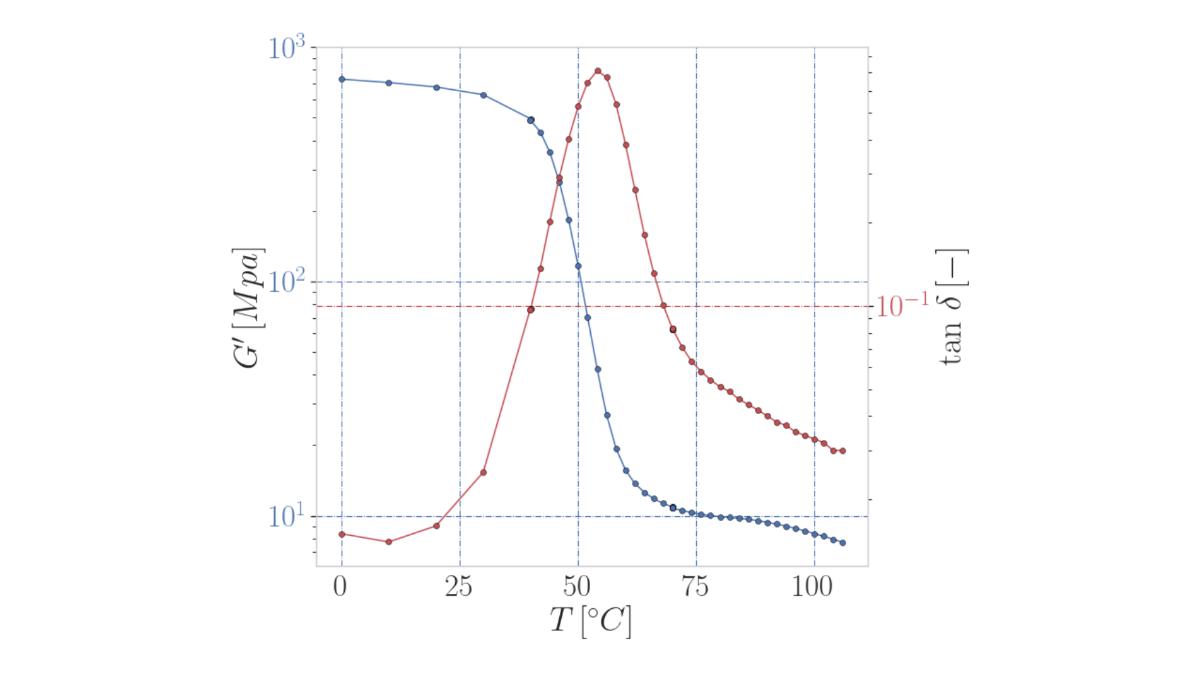

By means of the different measuring systems for the rheometer, it is possible to determine viscosities of liquids (with the existing plate-plate or cone-plate measuring system) as well as compression moduli on solid disk samples. Further measuring systems faciliate material characterization like, for instance, Solid Circular Fixture (SCF) or Solid Rectangular Fixture (SRF). Thanks to the above explained chambers, harmonic moduli with their dependency on temperature and humidity can be estimated. Frequency measurements additionally give the opportunity to resolve the time-dependent properties of viscoelastic materials.

Experiments

Publications

- Fauser, D. & Steeb, H. (2021). Humidity and thermal triggered Shape Memory Effect - Rheology-based numerical modelling - Dynamic Mechanical Thermal Humidity Analysis. DaRUS, V1. doi:10.18419/darus-2021

- Fauser, D., Kuhn, M., Steeb, H. (2021). Humidity and thermal triggered Shape Memory Effect - Rheology-based numerical modelling - Diffusion measurements. DaRUS, V1. doi:10.18419/darus-2024

- Fauser, D. & Steeb, H. (2021). Humidity and thermal triggered Shape Memory Effect - Rheology-based numerical modelling - Thermal Humid Mechanical Cycle. DaRUS, V1. doi:10.18419/darus-2023

- Fauser, D. & Steeb, H. (2022). Influence of humidity on the rheology of thermoresponsive shape memory polymers. Journal of Material Science, 57, 9508-9524. doi:10.1007/s10853-022-07206-8

- Ghobadi, E., Shutov, A., Steeb, H. (2021). Parameter Identification and Validation of Shape-Memory Polymers within the Framework of Finite Strain Viscoelasticity. Materials, 14. doi:10.3390/ma14082049

- Dingler, C., Müller, H., Wieland, M., Fauser, D., Steeb, H., Ludwigs, S. (2021). From Understanding Mechanical Behavior to Curvature Prediction of Humidity‐Triggered Bilayer Actuators. Advanced Materials, 33. doi:10.1002/adma.202007982

- Ghobadi, E., Elsayed, M., Krause-Rehberg, R., Steeb, H. (2018). Demonstrating the Influence of Physical Aging on the Functional Properties of Shape-Memory Polymers. Polymers, 10. doi:10.3390/polym10020107

- Ghobadi, E., Marquardt, A., Mahmoudinezhad Zirdehi, E., Neuking, K., Varnik, F., Eggeler, G., Steeb, H. (2018). The Influence of Water and Solvent Uptake on Functional Properties of Shape-Memory Polymers. International Journal of Polymer Science, 2018, 1-15. doi:10.1155/2018/7819353

For further information please contact

Dominik Fauser

M. Sc.Doctoral Researcher

[Image: Dominik Fauser]