Related Projects

About the XRCT Lab

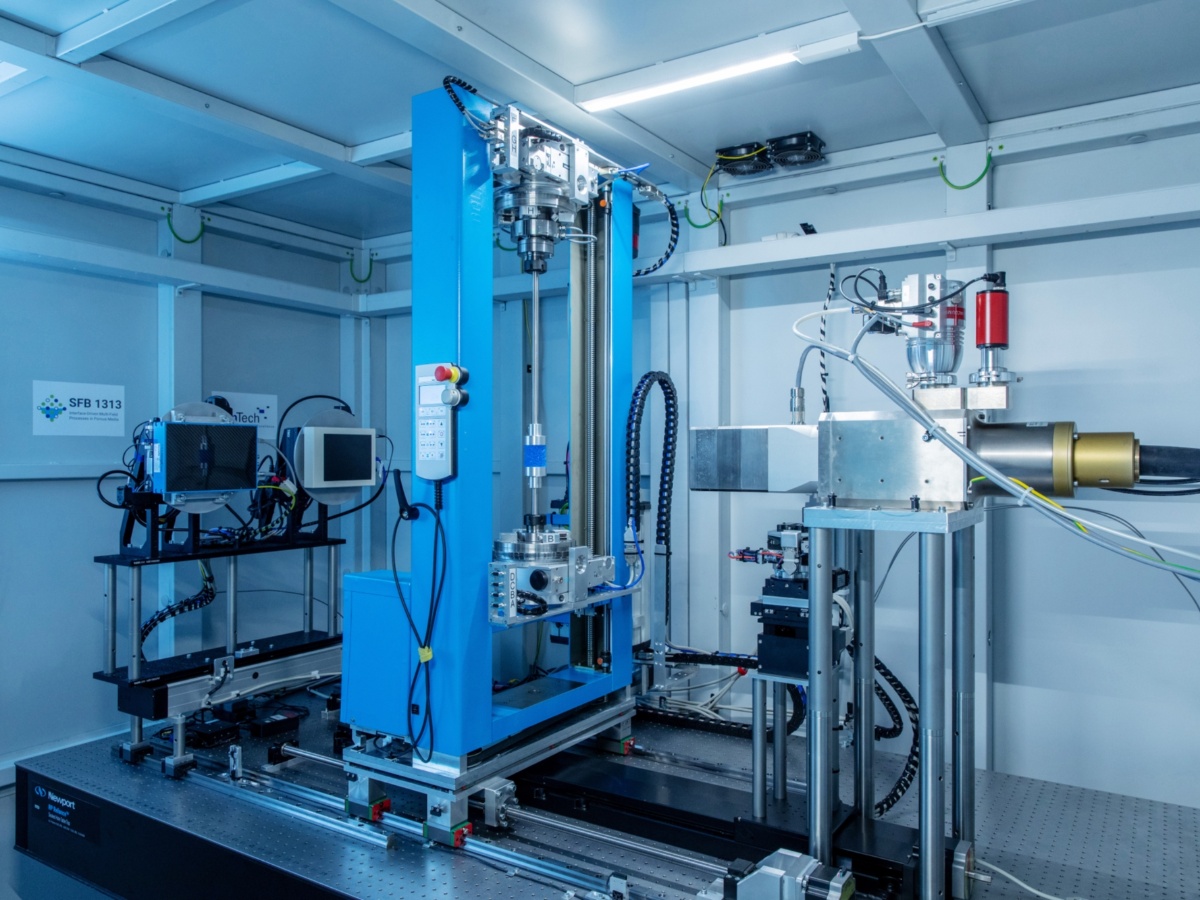

To obtain high resolution X-Ray Computed Tomography (XRCT) projection data for pore-scale investigations, the PML incorporates an in-house developed µXRCT system, meaning that the system gives an insight into details in the micrometer range. Since recently, there also exists the possibility to carry out uniaxial in situ experiments during the scanning process. The Institute of Applied Mechanics (CE) has the possibility to store around 300 TB of 'hot data' - however the goal is to publish relevant data sets including the underlying metadata on the Data Repository of the University of Stuttgart (DARUS), ensuring free access to everyone ('Open Access').

µXRCT system

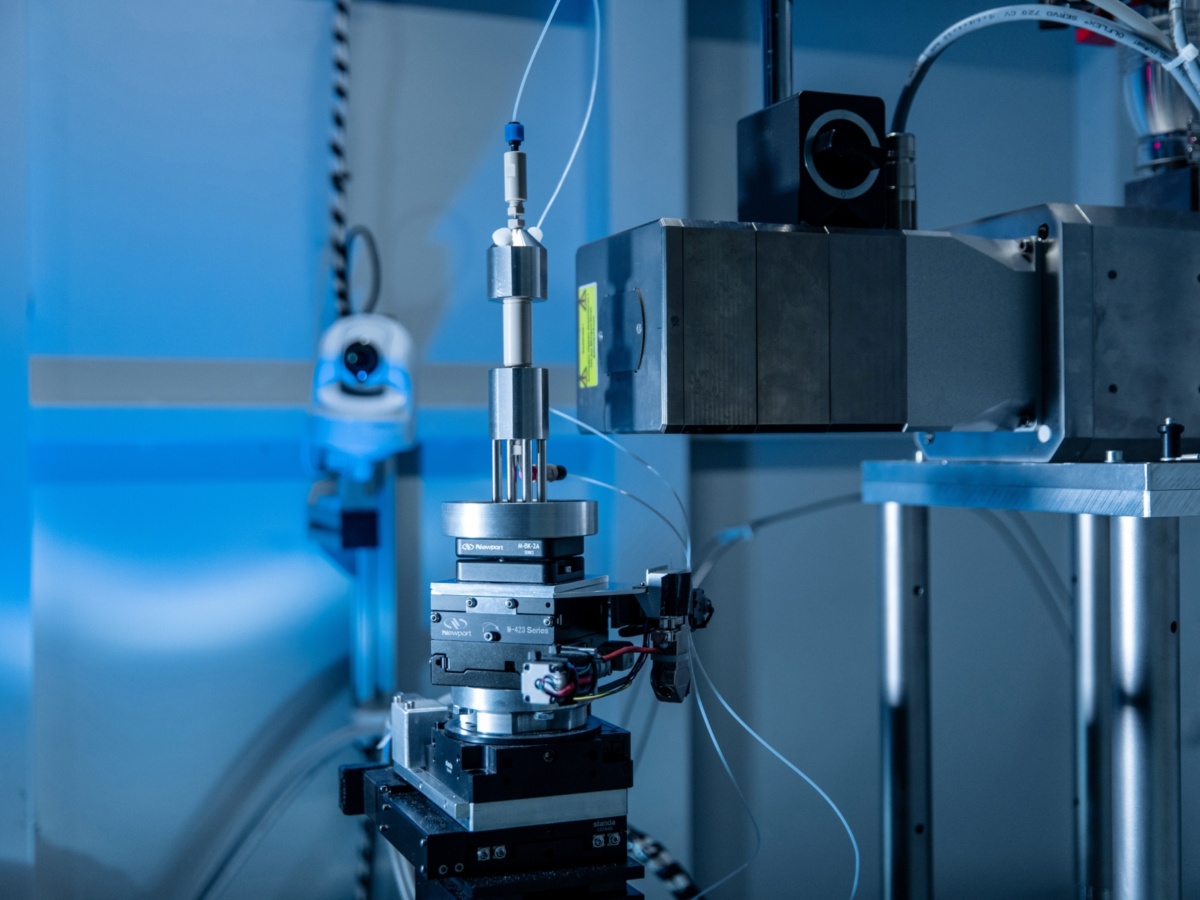

The core of the µXRCT system is the open micro-focus tube FineTec FORE 180.01C TT from FineTec Fine-Focus Technologies, providing a focal spot down to < 3 µm and a maximum power of up to 80 W. Two different CMOS (Complementary Metal-Oxide Semiconductor) based detectors, distinguishing in the scintillation option and resolution, are employed to measure the attenuated X-radiation between the X-ray source and the detectors.

- The PerkinElmer® Dexela 1512NDT detector with GOS (Gadolinium Oxysulfide) based standard scintillator option has a resolution of 1944x1536 pixels together with a pixel size of 74.8 µm.

- The Teledyne DALSA Shad-o-Box 6K HS utilizes a CsI (Caesium Iodide) scintillator to record projection images with a resolution of 2940x2304 pixels at a pixel size of 49.5 µm.

The whole system is installed on an optical table inside a lead-shielded cabin to avoid undesirable movement induced by the surrounding. Related to the specific investigation, stages can be exchanged and adopted.

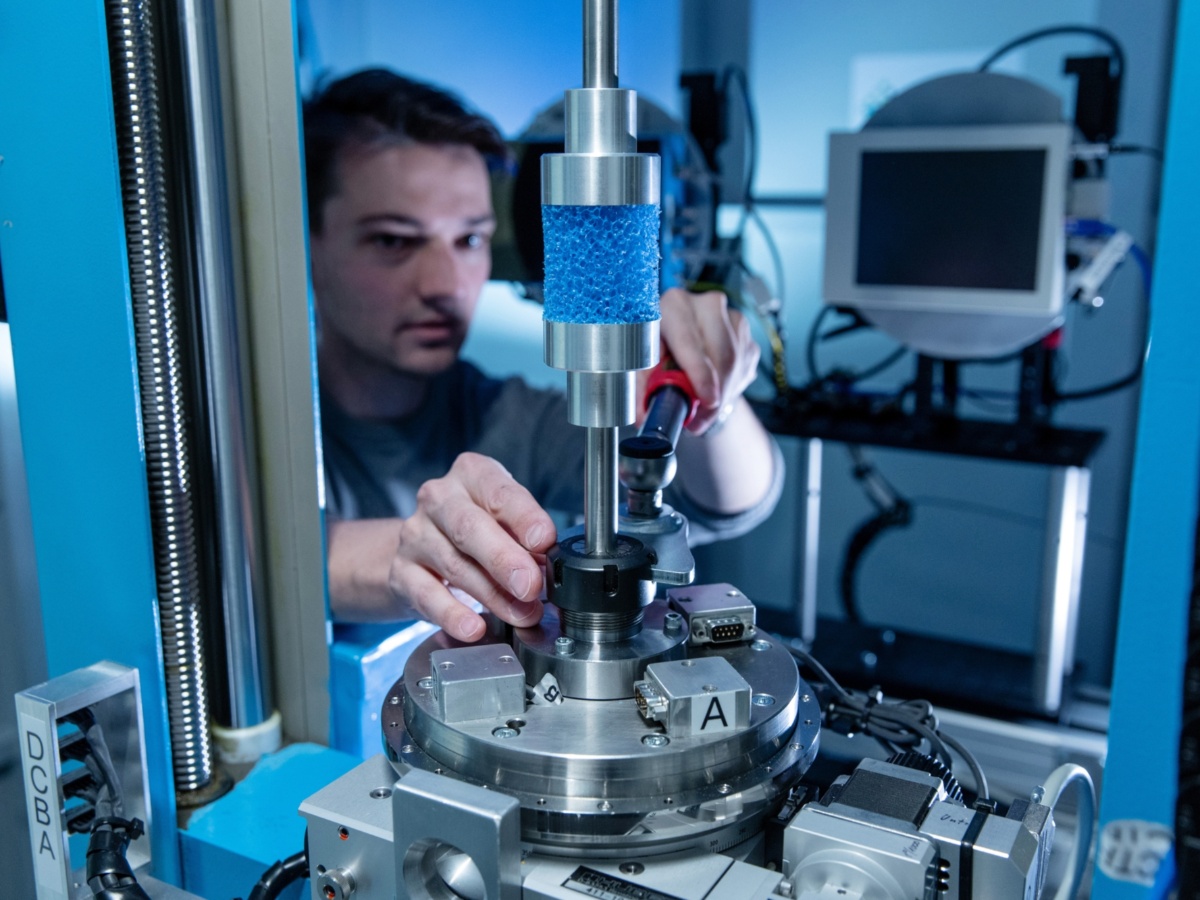

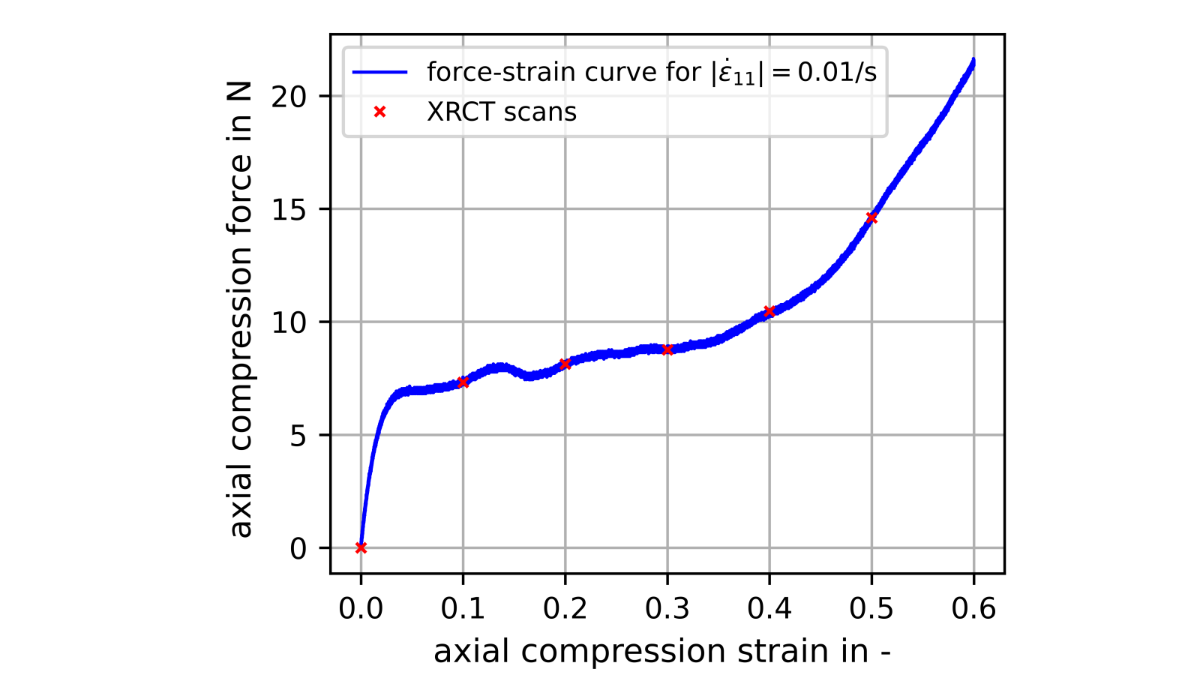

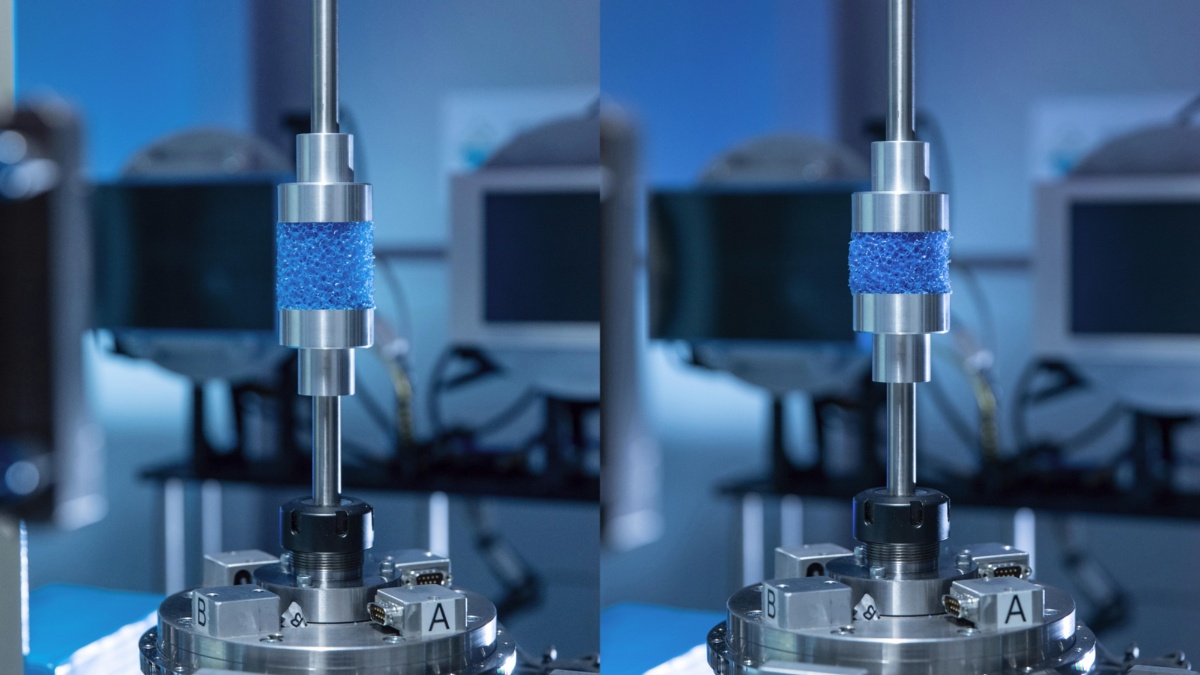

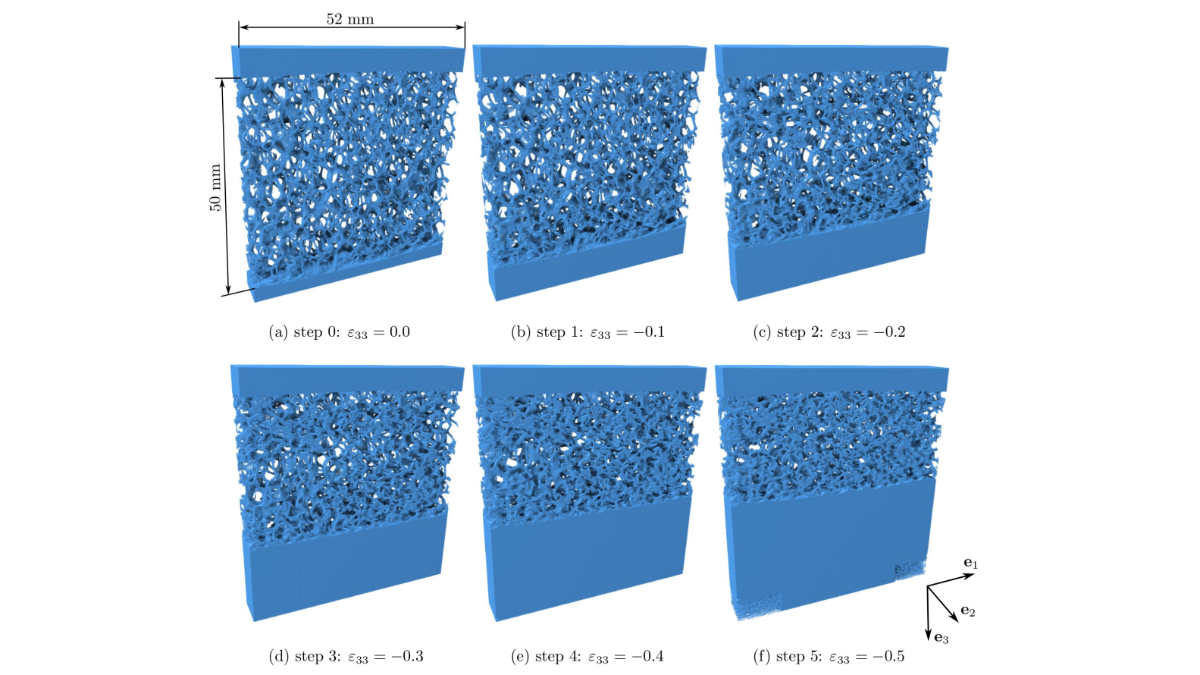

In situ experiments

To perform in situ experiments inside the XRCT Lab, the refurbished Zwick 1445 10 kN uniaxial testing device can be located in the passage between X-ray source and detector position, making it possible to run uniaxial trials with a compression/tension force of ±3.1 kN and torque up to ±15 Nm thanks to the two stiff rotational stages (XHuber 1-circle goniometer 411 X3 W2).

Besides solely mechanical experiments, also different X-ray transparent load cells for the investigation of hydraulic (flow cells with core diameter of 3 mm) and hydro-mechanical properties (triaxial cells with core diameter of 6 mm) can be used in the PML.

Experiments

Publications

- Balcewicz, M., Ruf, M., Steeb, H., Saenger, E. H. (2021). Digital Rock Physics: A Geological Driven Workflow for the Segmentation of Anisotropic Ruhr Sandstone: SEM images. DaRUS, V1, doi:10.18419/darus-1812

- Balcewicz, M., Ruf, M., Steeb, H., Saenger, E. H. (2021). Digital Rock Physics: A Geological Driven Workflow for the Segmentation of Anisotropic Ruhr Sandstone: segmented subvolumes. DaRUS, V1, doi:10.18419/darus-1435

- Ruf, M., Balcewicz, M., Saenger, E. H., Steeb, H. (2021). Digital Rock Physics: A Geological Driven Workflow for the Segmentation of Anisotropic Ruhr Sandstone: micro-XRCT data set. DaRUS, V1, doi:10.18419/darus-1152

- Vahid Dastjerdi, S., Steeb, H., Ruf, M., Lee, D., Weinhardt, F., Karadimitriou, N., Class, H. (2021). micro-XRCT dataset of Enzymatically Induced Calcite Precipation (EICP) in a microfluidic cell. DaRUS, V1. doi:10.18419/darus-866

- Ruf, M. & Steeb, H. (2020). micro-XRCT data set of Carrara marble with artificially created crack network: slow cooling down from 600°C. DaRUS, V1. doi:10.18419/darus-754

- Ruf, M. & Steeb, H. (2020). micro-XRCT data set of an in-situ flow experiment with an X-ray transparent flow cell. DaRUS, V1. doi:10.18419/darus-691

- Ruf, M. & Steeb, H. (2020). micro-XRCT data set of Carrara marble with artificially created crack network: fast cooling down from 600°C. DaRUS, V1. doi:10.18419/darus-682

- Ruf, M. & Steeb, H. (2020). micro-XRCT data set of an open-pored asphalt concrete. DaRUS, V1. doi:10.18419/darus-639

- Balcewicz, M., Siegert, M., Gurris, M., Ruf, M., Krach, D., Steeb, H., Saenger, E. H. (2021). Digital Rock Physics: A Geological Driven Workflow for the Segmentation of Anisotropic Ruhr Sandstone. Frontiers in Earth Science, 9. doi:10.3389/feart.2021.673753

- Hasan, N., Niasar, V., Karadimitriou, N., Godinho, J. R. A., Vo, N. T., An, S., Rabbani, A., Steeb, H. (2020). Direct characterization of solute transport in unsaturated porous media using fast X-ray synchrotron microtomography. Proceedings of the National Academy of Sciences, 117, 23443-23449. doi:

- Weinhardt, F., Class, H., Vahid Dastjerdi, S., Karadimitriou, N., Lee, D., Steeb, H. (2021). Experimental Methods and Imaging for Enzymatically Induced Calcite Precipitation in a Microfluidic Cell. Water Resources Research, 57. doi:10.1029/2020WR029361

- Lissa, S., Ruf, M., Steeb, H., Quintal, B. (2020). Effects of crack roughness on attenuation caused by squirt flow in Carrara marble. SEG Technical Program Expanded Abstracts 2020, 2439-2443. doi:10.1190/segam2020-3427789.1

- Ruf, M. & Steeb, H. (2020). An open, modular, and flexible micro X-ray computed tomography system for research. Review of Scientific Instruments, 91. doi:10.1063/5.0019541

- Hermann, S., Schneider, M., Flemisch, B., Frey, S., Iglezakis, D., Ruf, M., Schembera, B., Seeland, A., Steeb, H. (2020). Datenmanagement im SFB 1313. Bausteine Forschungsdatenmanagement, 1, 28-38. doi:10.17192/BFDM.2020.1.8085

For further information please contact

Matthias Ruf

Dr.-Ing.Postdoc

[Image: Matthias Ruf]